THE DESIGN

Robert stumbled across Brian Waite’s amazing cruck-frame design around 2012 while surfing the net for strawbale house plans (www.strawbalehouse.co.uk). Brian, a retired engineer, came up with a concept for an easy-to-build, highly insulated starter home that would be based around a cruck frame and using strawbales as the cheap, ‘filler’ insulation. To prove his design he set about building one in his back garden, not letting his dodgy knee put him off. He even constructed the crucks himself in a nearby polytunnel using dozens of clamps. We were capitvated by the simplicity of the design and the beautiful curve of the roof, much like an upturned rowing boat. We went down to Cockermouth to meet Brian, see his house and find out whether we might be able to copy his design as we had just enough space on our elevated site for a pair of strawbale houses. Over the next few years we worked with him, his recommended passive-house, timber frame company (Touchwood Homes) and a Lochaber-based architect (David Mee) to make our dream a reality.

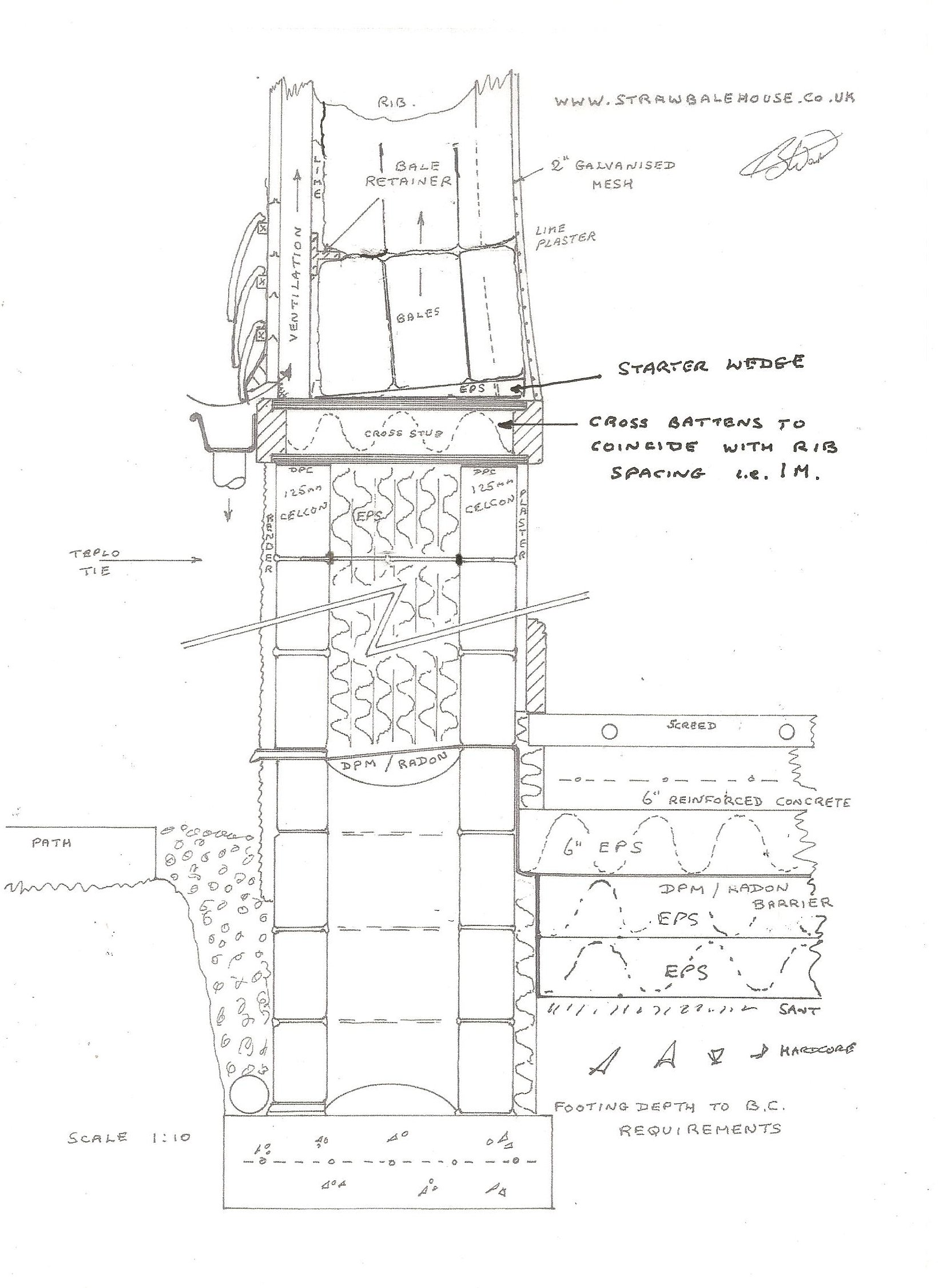

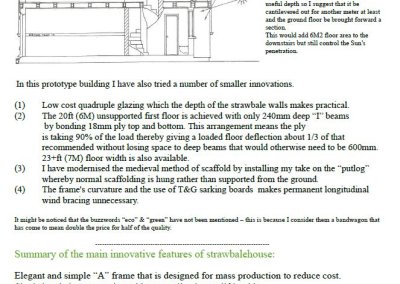

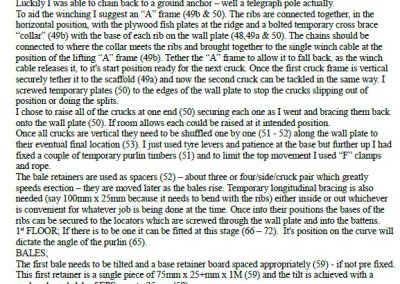

Cross-section through the wall

One of the many hand-drawn designs created by Brian. A thing of real beauty (who needs ‘Computer Aided Design’?). Brian’s attention to detail is wonderful. You can see the thin wedge of polystyrene that starts the first bale off at the right angle. The wooden horizontal bale spacers/retainers between each bale attach to each cruck and help keep the structure rigid and also fill the gap at the outside of the bale made by the curve of the crucks. The dwarf wall keeps the strawbales a minimum of 900mm above ground level which ensures they stay dry. The 300mm of expanded polystyrene between the two aircrete block walls provides the same level of insulation as the width of the strawbales. The straw is covered on the inside by galvanised fencing mesh and then two layers of lime mortar that were sprayed on. The outside of the straw is covered in one coat of hydrated lime.

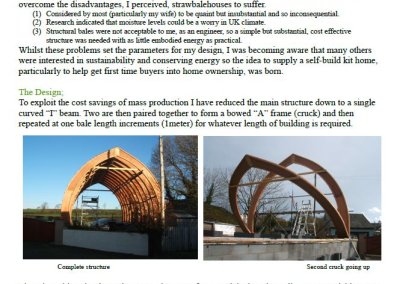

Brian demonstrates the feasibility of his concept by building a strawbale house in his back garden.

This series of photos takes you – briefly – through some of the key stages of the building process of Brian’s prototype in Cockermouth. From the laying of the foundations, through to the building of the insulated ‘dwarf’ walls, the construction of the ‘I’ crucks in the neighbouring polytunnel, their raising and filling in with strawbales. This is followed by the spraying on the lime and putting the roof on with the curved, clay tiles leaving a breathing space above the lime to allow the ‘chimney effect’ to draw excess moisture from the lime to keep the straw bone dry. The increasingly damp air moving across the external lime can vent at the ridge. This was a bit of genius design by Brian to ensure that the straw stayed dry. The internal lime in all three strawbale houses is so dry that it is too low for moisture meters to produce a reading.

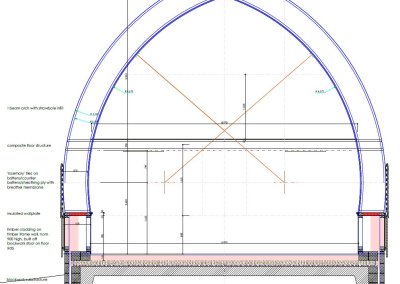

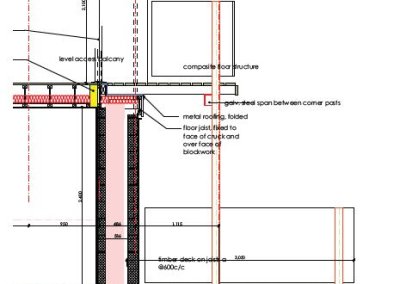

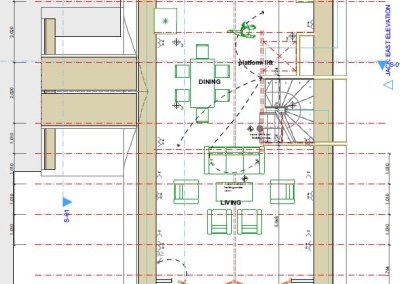

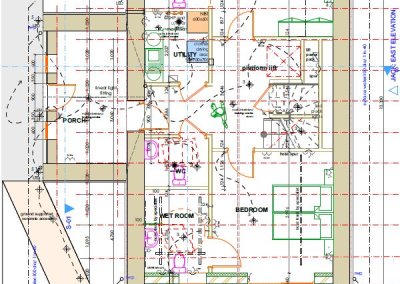

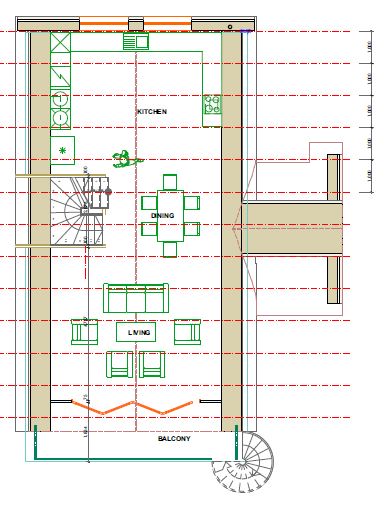

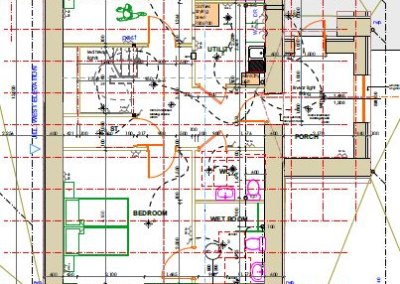

Here are a few of the CADs that our architect – David Mee produced:

davidmee-architect.co.uk

Without David’s expertise, guidance and local knowledge of the build-approval process we would never have been able to obtain planning permission (unexpectedly easy), building control approval or – quite simply – put Brian’s design into practice here in Lochaber with different layouts, the added porch (using smaller crucks) and the front decks.